Welding Safety: Preventing Electrocution – Your Life Depends on It (WeldSafe Essentials 3)

Electricity is the silent powerhouse behind every welding arc, but it’s also one of the deadliest hazards on the job. A single lapse in precaution can send thousands of volts through your body, causing severe burns, cardiac arrest, or instant death. In WeldSafe Essentials #3, we focus on electrical safety fundamentals—starting with the golden rule: always isolate power before maintenance or movement, avoid live parts at all costs, and never weld with wet hands. These aren’t suggestions; they’re survival protocols backed by decades of incident data.

Why Welding Electricity Kills So Efficiently

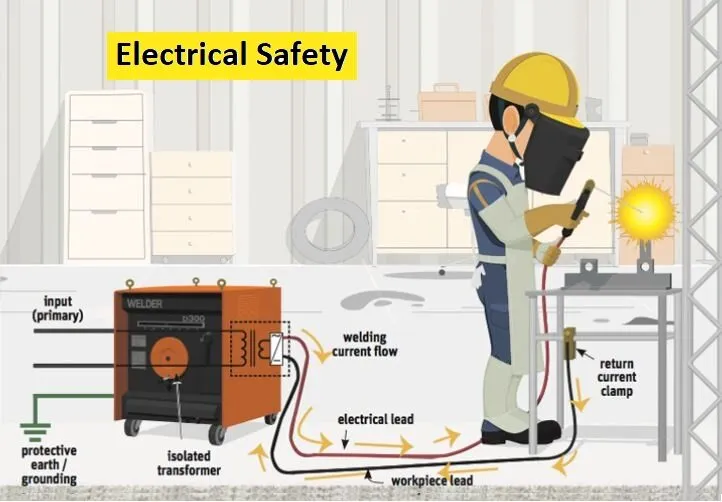

Welding machines operate at high amperage (often 100–500+ amps) and low voltage (typically 20–80V open-circuit), but even these “safe” voltages become lethal when your body provides a path to ground—especially through sweat, water, or metal contact. The real danger? Secondary shock from damaged cables, poor grounding, or accidental contact with electrode holders while current is live.

OSHA reports that electrocution accounts for about 12% of all construction worker deaths, with welding being a top contributor. Most incidents occur not during active welding, but during setup, maintenance, or equipment relocation—exactly when workers let their guard down.

Real Case: A welder in Texas was fatally shocked while adjusting a machine with the power still on. The breaker was just 10 feet away—but he didn’t flip it.

Core Electrical Safety Rules You Must Follow

1. Always De-Energize Before Touching Equipment

- Before repair, inspection, or moving any welding machine, lock out and tag out (LOTO) the power at the distribution panel.

- Use a voltage tester to verify zero energy on all terminals—even after the switch is off.

- Never assume “it’s unplugged.” Trace the cord to the outlet and confirm.

Pro Tip: Attach a personal lock and tag with your name and date. Only you remove it.

2. Never Touch Live Parts—Ever

- The electrode holder, ground clamp, and cable connections can carry lethal current when the machine is on.

- Treat all metal parts of the welding circuit as live until proven otherwise.

- Use insulated pliers or hot gloves if you must handle connections under load (rare and only by qualified personnel).

3. No Wet Hands, No Exceptions

- Water reduces skin resistance dramatically—a wet hand can turn 50V into a death sentence.

- Dry your hands, gloves, and workpiece thoroughly.

- Avoid welding in rain, puddles, or high-humidity environments without proper enclosures (IP-rated machines).

- Wear dry, hole-free leather gloves and rubber-soled boots rated for electrical hazard (EH).

4. Inspect Cables and Connections Daily

- Look for:

- Frayed insulation

- Exposed copper

- Loose lugs

- Overheated terminals (discoloration)

- Replace damaged cables immediately—duct tape is not insulation.

- Route cables away from sharp edges, oil, and heat.

5. Proper Grounding Saves Lives

- Connect the work clamp directly to the workpiece—never to building steel or scaffolding unless verified as part of the circuit.

- Avoid daisy-chaining grounds through multiple pieces.

- Use GFCI (Ground Fault Circuit Interrupter) protection on all 120V/240V outlets feeding welders.

Safe Maintenance Checklist

| Task | Safety Step |

|---|---|

| Moving welder | Unplug, coil cables, secure wheels |

| Changing electrode | Power OFF, wait 2 minutes for capacitor discharge |

| Tightening lugs | LOTO + insulated tools |

| Cleaning machine | Compressed air only—no liquids |

Emergency Response: Shock Protocol

If someone is electrocuted:

- Do NOT touch them—they’re live.

- Shut off power at the breaker.

- Call emergency services.

- If safe, use a non-conductive tool (wood, plastic) to separate victim from source.

- Begin CPR if trained and safe.

Quick Reference: Electrical Safety Do’s and Don’ts

- DO LOTO before maintenance

- DO use insulated tools and PPE

- DO inspect cables before each shift

- DON’T weld with wet gloves or standing in water

- DON’T bypass breakers or use undersized extension cords

- DON’T assume “low voltage” means “safe”

Print and post this near every welding station.

Conclusion: Respect the Current

Electrocution doesn’t give second chances. One moment of carelessness—reaching for a live cable with damp hands or skipping LOTO—can end a career or a life. Make electrical safety non-negotiable: isolate power, stay dry, inspect rigorously. Your heartbeat depends on it.

Check our previous blog on the topic of Welding Safety: Eliminating Fire Hazards from Flammable Materials (WeldSafe Essentials 2)