Welding Safety: Machine Case Grounding – The Hidden Shock You Never See Coming (WeldSafe Essentials 6)

A welding machine’s metal case looks harmless—until insulation inside fails or lightning strikes. At that moment, the entire chassis can become energized with lethal voltage. In WeldSafe Essentials 6, we cover one of the simplest yet most neglected life-saving requirements: dedicated case grounding (equipment grounding conductor) for every welder. Skipping this step has killed welders who never even touched a live electrode.

Why Case Grounding Is Non-Negotiable

Welding machines contain transformers, capacitors, and rectifiers that can leak current to the metal housing if insulation breaks down. Common triggers:

- Internal wire chafing

- Water ingress

- Overheating components

- Lightning-induced surge

Without a low-resistance path to earth, that fault current will happily flow through you the moment you touch the machine and a grounded object (pipe, scaffold, wet floor, etc.).

Fatal Example: In 2022, a welder in Brazil was killed instantly while leaning against his engine-driven welder during a rainstorm. The machine had no case ground wire—lightning surged through the frame and into his body.

The Correct Way to Ground the Welder Chassis

Dedicated Green or Bare Copper Ground Wire

- Must run from the grounding terminal (usually marked with ⏚ or “PE”) on the welder directly to a verified earth point.

- Never rely on the power cord’s ground pin alone for older portable welders.

Separate from Workpiece Ground

- The work lead (clamp to workpiece) carries welding current.

- The case ground is only for safety and must be independent.

Connection Points

- Building steel (if certified as grounding electrode)

- Ground rod driven ≥8 ft

- Cold water pipe (code-approved)

- Never use gas pipes or aluminum siding.

Wire Sizing (per NEC & IEC) Minimum equipment grounding conductor size:

Welder Input Current Min. Ground Wire (Copper) ≤100 A 10 AWG 100–200 A 8 AWG >200 A 6 AWG or larger Engine-Driven Welders

- Bond the welder frame to the generator frame.

- Connect both to a ground rod at the job site (required by OSHA 1926.404(f)(3)).

Daily Verification Checklist

Before plugging in:

- Green/bare ground wire securely attached at both ends

- No paint or rust under grounding lug (scrape clean)

- Continuity test: <0.1 Ω from chassis to earth (use a proper ground tester)

- No daisy-chaining multiple machines on one ground wire

What NOT to Do

- × Use the work clamp cable as case ground

- × Skip grounding because “it’s only 220V”

- × Trust the three-prong plug on portable welders without verifying the outlet is grounded

- × Ignore flickering lights or tingling when touching the machine—those are warning signs!

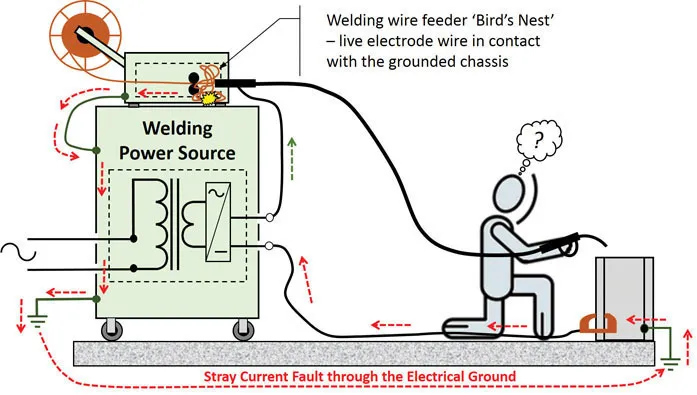

Quick Reference Diagram

[Earth Ground] ←── Green/Bare Wire ──⏚[Welder Chassis]

│

Separate from

│

[Work Clamp] ←── Welding Cable

10 Seconds That Save Lives

Attaching a proper case ground takes less than a minute and costs almost nothing. Yet it’s the difference between a minor internal fault and a funeral. Make it part of every setup: no ground wire = no weld.