Welding Safety: Installing the Liner and Setting Contact Tip Protrusion – Precise Setup for Smooth Feeding (WeldSafe Essentials 12)

Proper installation of the MIG torch liner and correct protrusion of the contact tip are critical final steps in torch assembly. A misaligned liner or incorrect tip length causes feeding issues, arc instability, premature wear, and poor weld quality. In WeldSafe Essentials #12, we cover the clockwise rotation method for inserting the liner and the recommended protrusion length (L) for the contact tip based on torch cable length.

Step 1: Installing the Liner Correctly

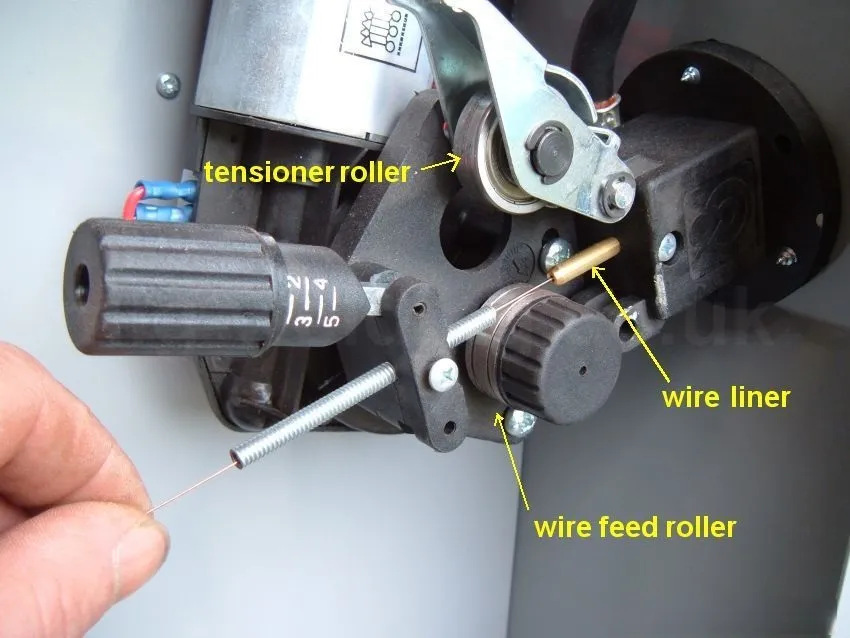

To insert the liner smoothly into the torch cable:

- Align the liner with the torch cable inlet.

- Rotate the torch cable clockwise (following the arrow direction indicated on many torches) while gently pushing the liner forward.

- The clockwise twist helps the liner follow the natural spiral of the cable without kinking or binding.

- Continue until the liner seats fully against the internal stop or diffuser (refer to your torch manual for exact seating).

This technique prevents twisting damage and ensures the liner sits straight for minimal resistance.

Step 2: Trimming the Contact Tip

New contact tips are often supplied longer than needed to accommodate different setups:

- Refer to your torch or welder manual for the exact recommended protrusion length.

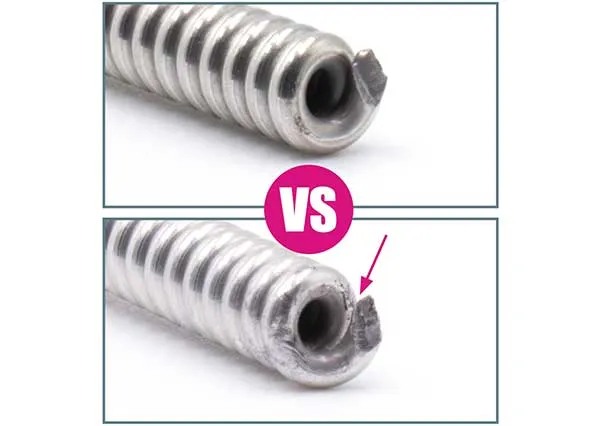

- Cut the tip to the proper length using a sharp cutter or hacksaw.

- Smooth the cut end with fine sandpaper or a file to remove burrs—sharp edges can shave wire or cause inconsistent contact.

A properly trimmed tip ensures optimal stick-out, good electrical contact, and prevents excessive spatter buildup.

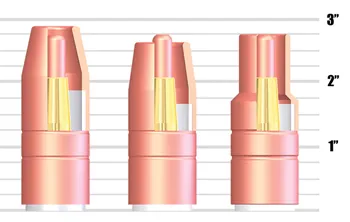

Recommended Contact Tip Protrusion Length (L)

The protrusion length L (distance from the end of the nozzle to the tip end) varies with torch cable length to maintain proper wire stick-out and gas coverage:

| Torch Cable Length (m) | Recommended Protrusion L (mm) |

|---|---|

| 3 | 7–10 |

| 4.5 | 9–12 |

| 6 | 11–14 |

- Shorter cables need less protrusion; longer cables require more to compensate for natural wire curvature and maintain arc stability.

- Always measure L after installation and adjust if needed.

Quick Setup Checklist

- Rotate torch cable clockwise while pushing liner until fully seated

- Trim contact tip to match cable length table

- Sand/file cut end smooth (no burrs)

- Verify tip seats flush in diffuser/nozzle

- Test feed wire manually—should move freely without resistance

Precision in the Final Inches

Clockwise rotation during liner insertion and accurate contact tip protrusion are small details that deliver big results: consistent wire feeding, stable arcs, and longer consumable life. Follow the arrow, measure L precisely, and deburr edges—your welds will thank you.

Had feeding troubles fixed by a simple liner twist or tip trim? Share your tip below.