Blog

Seguridad en Soldadura: Ubicación correcta de la soldadora - Proteja su máquina y a usted mismo (WeldSafe Essentials 7)

Su máquina de soldar es una herramienta de precisión que vale miles de dólares, pero exponerla a la lluvia, el sol directo, las temperaturas extremas, la humedad elevada o el polvo puede destruir los componentes internos, anular las garantías y crear riesgos de seguridad ocultos como la rotura del aislamiento o fallos eléctricos. En WeldSafe Essentials #7, cubrimos las condiciones ambientales recomendadas por el fabricante para la instalación y el almacenamiento de soldadoras: pautas sencillas que prolongan la vida útil del equipo y evitan fallos peligrosos.

Por qué es importante la ubicación de la instalación

El agua, el calor, el frío, la humedad y el polvo son asesinos silenciosos de los equipos de soldadura:

- Lluvia o goteos de agua → Corrosión, cortocircuitos, riesgo de electrocución.

- Luz solar directa → Sobrecalentamiento de los componentes electrónicos, etiquetas descoloridas, plásticos degradados.

- Temperaturas extremas → Tensión de los componentes, fallo de los condensadores, ciclo de trabajo reducido.

- Humedad elevada → Condensación en el interior de los circuitos, óxido en los transformadores.

- Polvo y escombros → Ventiladores obstruidos, sobrecalentamiento, inestabilidad del arco.

Una soldadora instalada en un garaje húmedo o abandonada bajo un tejado con goteras puede desarrollar fallos invisibles que energicen la carcasa o provoquen incendios espontáneos, incluso cuando está apagada.

Requisitos de instalación ideales

Instale siempre su soldadora en el interior en un lugar que cumpla estas condiciones:

Protegido de la intemperie

- Sin lluvia, goteo de agua ni salpicaduras

- Sin luz solar directa (los rayos UV degradan el aislamiento y las pantallas)

Entorno limpio y controlado

- Poco polvo: Evite las naves de amolado, las zonas de chorro de arena o las zonas de construcción.

- Buena circulación de aire pero sin suciedad forzada (por ejemplo, no junto a puertas abiertas en zonas ventosas)

Pautas de temperatura

Condición Rango de temperatura Durante la operación de soldadura De -10°C a +40°C (de 14°F a 104°F) Transporte y almacenamiento -20°C a +55°C (-4°F a 131°F) El funcionamiento fuera de estos límites reduce el rendimiento y puede provocar cortes térmicos o daños permanentes.

Límites de humedad relativa

Temperatura ambiente Humedad relativa máxima 40°C ≤50% 20°C ≤90% Una mayor humedad a temperaturas elevadas acelera la condensación y la corrosión.

Mejores prácticas para la selección del emplazamiento

- Ubicación preferida: Cabina de soldadura dedicada o rincón de taller limpio con techo y paredes sólidas

- Eleve la máquina: Colóquela sobre un palé o soporte no conductor (a una distancia mínima de 15 cm del suelo) para evitar que se inunde de agua y mejorar el flujo de aire de refrigeración.

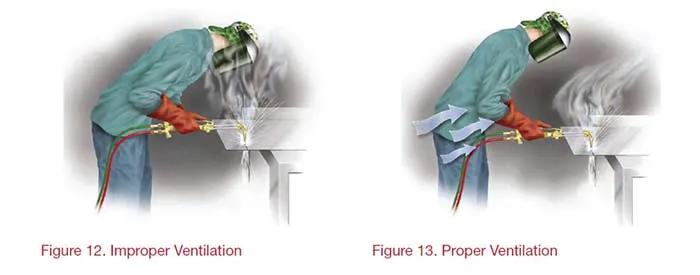

- Ventilación: Garantice un espacio libre de al menos 12-18 pulgadas en todos los lados para la entrada/salida del ventilador

- Estabilidad de la fuente de alimentación: Evite las zonas con fuertes fluctuaciones de tensión o los circuitos compartidos con grandes motores

Instalaciones temporales o en obra

- Utilice cubiertas o envolventes resistentes a la intemperie con clasificación IP54 o superior

- Nunca deje las máquinas a la intemperie durante la noche sin protección

- En climas fríos, deje transcurrir un tiempo de calentamiento antes de utilizarlo si se almacena por debajo de 0°C

Lista de comprobación rápida del cumplimiento

Antes de poner en marcha una soldadora nueva o trasladada:

- En interiores, sin riesgo de lluvia o goteo de agua

- Sin exposición directa a la luz solar

- Temperatura ambiente entre -10°C y +40°C

- Humedad relativa por debajo de los límites especificados

- Polvo mínimo - ventiladores y respiraderos limpios

- Espacio libre mínimo alrededor de la máquina

- Colocada sobre una superficie seca, nivelada y no conductora

Consecuencias de una mala instalación

| Asunto | Resultado |

|---|---|

| Exposición al agua | Peligro inmediato de descarga, garantía anulada |

| Humedad elevada prolongada | Óxido interno, fallo del condensador |

| Acumulación de polvo | Sobrecalentamiento, ciclo de trabajo reducido, riesgo de incendio |

| Arranque en frío extremo | Componentes frágiles, fallo de arranque |

La ubicación es la prevención

Elegir el lugar de instalación adecuado lleva unos minutos, pero ahorra miles en reparaciones y tiempos de inactividad, a la vez que elimina peligros eléctricos ocultos. Trate a su soldadora como el instrumento de precisión que es: manténgala seca, fresca, limpia y a la sombra.