Blog

Sécurité en soudage : Maintenir le câble de la torche MIG aussi droit que possible - Pour une alimentation en douceur et des arcs stables (WeldSafe Essentials 13)

The MIG torch cable is a flexible lifeline that carries wire, gas, power, and control signals—but excessive bending turns it into a major source of resistance. In WeldSafe Essentials #13, we explain why keeping the torch cable as straight as possible is critical for consistent wire feeding, stable arcs, and reduced wear on the entire system.

The Problem with Severe Bending

When the torch cable is sharply bent or coiled tightly:

- Increased wire feeding resistance — The liner inside the cable compresses and creates friction points, making the wire feeder work harder.

- Inconsistent wire speed — Speed surges and drops cause stubbing, burn-back, or erratic arc length.

- Arc instable — Fluctuating wire delivery leads to spatter, porosity, poor penetration, and undercut.

- Premature wear — Excessive bending stresses the liner, contact tip, and drive rolls, shortening consumable life.

The longer the torch cable, the worse the effect becomes: small bends create proportionally larger resistance over distance.

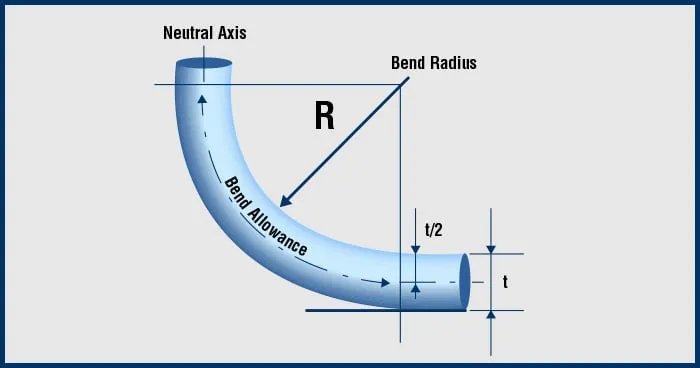

Recommended Practice: Minimum Bend Radius

- Keep bends gentle — Maintain a minimum bend radius of 300 mm (≈12 inches) or larger whenever possible.

- Ideal state — Use the torch cable in a nearly straight or only slightly curved path from the feeder to the welding point.

- Avoid tight coils, sharp 90° turns, wrapping around obstacles, or letting the cable hang in tight loops.

Règle empirique: The longer the torch cable (e.g., 4.5 m or 6 m), the larger you should keep the bend radius to compensate for cumulative resistance.

Visual Comparison

Here are examples showing proper vs. problematic torch cable routing:

- Left: Gentle curve with large radius → smooth feeding

- Right: Tight bends and coils → high resistance, unstable arc

Quick Setup Tips

- Position the wire feeder as close as practical to the work area to minimize cable length needed.

- Use cable hangers, supports, or boom arms to keep the torch cable elevated and gently curved.

- Avoid routing underfoot, around corners, or through tight passages.

- During breaks, drape the torch cable loosely over a hook—never coil it tightly.

- Test feed manually before striking an arc: pull wire by hand—if it feels gritty or resistant, straighten the cable first.

Quick Checklist Before Welding

- Torch cable mostly straight or gently curved

- No tight bends smaller than 300 mm radius

- No coils or wraps around equipment

- Cable supported to prevent dragging or kinking

- Manual wire feed feels smooth and consistent

Straight Cable = Stable Welds

A nearly straight torch cable is one of the easiest and cheapest ways to improve MIG welding performance. Respect the 300 mm minimum bend radius, especially on longer torches, and you’ll notice smoother feeding, cleaner arcs, and fewer bird-nests or burn-backs. Small routing changes deliver big quality gains.