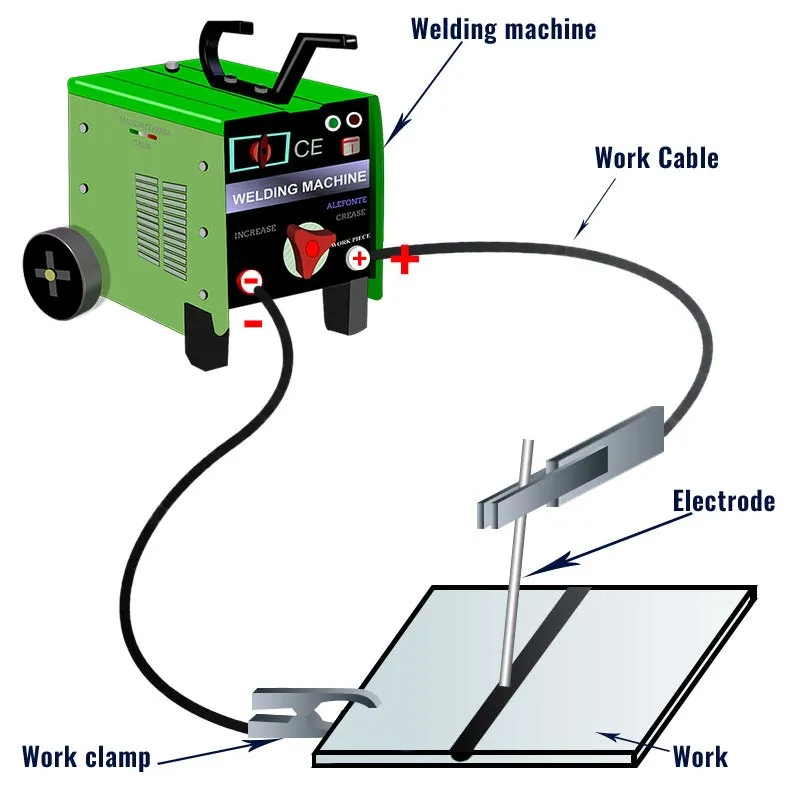

Welding Safety: Proper Work Lead (Ground Cable) Connections – For Stable Arcs and Safe Operation (WeldSafe Essentials 10)

The work lead—also called the ground cable or return cable—is just as important as the electrode cable, yet it’s often treated as an afterthought. Using improvised materials, undersized cables, or sharing grounds between machines leads to unstable arcs, poor weld quality, and hidden safety risks. In WeldSafe Essentials #10, we cover the correct way to connect and manage work leads to ensure consistent performance and prevent electrical hazards.

Why the Work Lead Matters

The work lead completes the welding circuit. Any resistance, poor contact, or improper setup causes:

- Unstable arc → excessive spatter, lack of penetration, porosity

- Voltage drop → reduced power at the arc, machine overheating

- Stray current → shock hazard to workers touching the workpiece or structure

- Sparking at connections → fire risk

Never treat the work lead as “just a ground”—it carries the full welding current.

Key Rules for Correct Work Lead Connection

1. Use Proper Welding-Grade Cable Only

- Never substitute steel plate, rebar, scaffolding, or building steel for the work lead cable. These create high-resistance paths and uncontrolled current flow.

- Never use undersized or damaged cable. It must match or exceed the electrode cable in cross-section and current rating.

2. When Multiple Welders Are in Use

- Do NOT share one common work lead between machines. Each welder needs its own independent return path to avoid current imbalance and interference.

- Do NOT run multiple work leads parallel and close together. Parallel cables induce electromagnetic interference, causing arc instability (“arc blow”). Space them at least 12 inches (30 cm) apart or route separately.

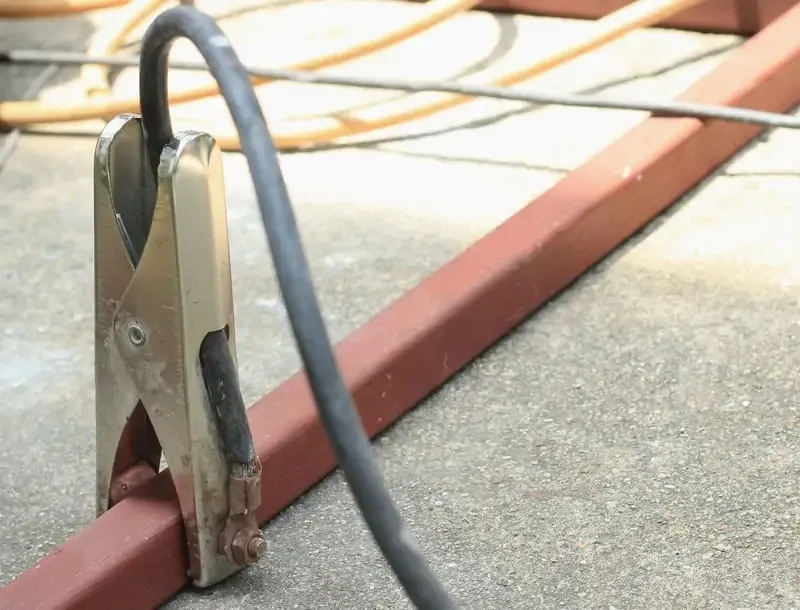

3. Secure and Clean Connections

- Attach the work clamp directly to the workpiece or a clean, conductive part of the fixture.

- Use a high-quality ground clamp with strong spring pressure, clean copper jaws, and good contact surface.

- Remove rust, paint, scale, or oil from the attachment point—scrape or grind to bright metal for low-resistance contact.

4. Proper Grounding

- The work lead provides the welding circuit return, but the machine chassis must still have its separate safety ground (as covered in #6).

- Never rely on the work clamp as the equipment safety ground.

Best Practices Summary

| Do ✓ | Don’t ✗ |

|---|---|

| Use dedicated welding cable sized for full current | Substitute rebar, plate, or structure steel |

| One independent work lead per welder | Share ground cables between machines |

| Space parallel cables apart | Run multiple work leads bundled together |

| Clamp to clean, bare metal on workpiece | Attach to painted or rusty surfaces |

| Inspect clamp jaws and cable daily | Use damaged or undersized cable |

Quick Daily Check

- Work cable insulation intact, no exposed copper

- Clamp jaws clean and spring strong

- Connection point scraped clean

- No shared grounds with other welders

- Cables routed separately from others

Treat the Return Path with Respect

A properly connected work lead gives you a stable, controllable arc and eliminates stray current dangers. Skip the shortcuts—no rebar, no shared grounds, no parallel runs, and always a clean, tight clamp. Your welds will be better, and your shop will be safer.

Ever fought arc instability that turned out to be a bad ground connection? Share your fix below.