Welding Safety: Timely Replacement of Worn Contact Tips – Maintain Precision and Stability (WeldSafe Essentials 14)

The contact tip (also known as the copper tip or electrode tip) is the critical point where welding current transfers to the wire, but it wears down quickly from friction, heat, and spatter. Ignoring wear leads to off-center arcs, poor conductivity, and erratic performance. In this paragraph we highlight why you must replace worn contact tips promptly to avoid shifted wire alignment and unstable current—ensuring clean, consistent MIG welds every time.

Signs and Consequences of Worn Contact Tips

Contact tips are consumables that last 8–40 hours depending on wire type, amperage, and material (e.g., steel vs. aluminum). As the tip’s bore enlarges from wear:

- Wire Alignment Shift

- The wire no longer centers properly in the arc, causing it to wander or misdirect.

- Result: Off-center welds with uneven penetration, excessive spatter, or lack of fusion—your bead looks wavy or incomplete.

- Reduced Electrical Conductivity

- Enlarged holes increase air gaps between wire and tip, raising resistance.

- Result: Unstable current leading to arc flickering, frequent breakouts (stubbing or burn-back), and voltage instability. In severe cases, it triggers machine error codes or shutdowns.

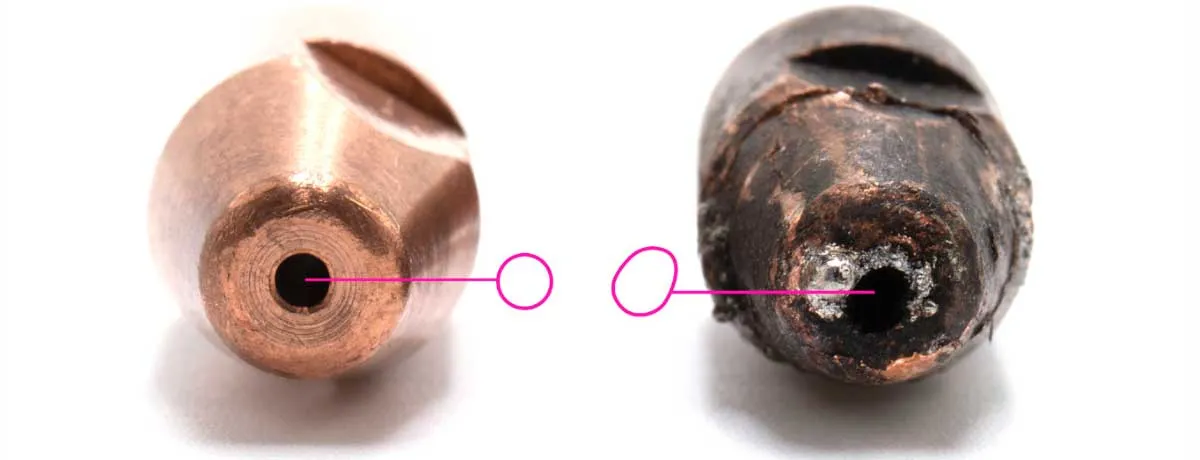

Visual cues of wear:

- Bore diameter exceeds wire size by >0.2 mm (e.g., 1.0 mm wire in a 1.3+ mm hole).

- Tip exterior shows melting, ovaling, or buildup.

- Wire feeding feels “sloppy” or inconsistent.

Pro Tip: For high-amperage or aluminum welding, inspect tips after every 4–6 hours—aluminum’s softness accelerates wear.

When and How to Replace

- Frequency: Replace at the first sign of arc instability or during routine maintenance (e.g., every tank of gas or 10–20 lbs of wire).

- Inspection Method: Remove the tip, measure the bore with a go/no-go gauge or caliper, and compare to your wire diameter (tip bore should be 0.1–0.3 mm larger than wire for optimal contact).

Quick Replacement Steps:

- Power off and lock out the welder.

- Disconnect the nozzle and remove the old tip (usually twists off).

- Select a new tip matching your wire diameter and material (e.g., standard copper for steel, chrome-plated for spatter resistance).

- Install hand-tight plus 1/4 turn (or per manual torque).

- Reassemble and test-feed wire—ensure smooth exit centered in the nozzle.

Comparison: Worn vs. New Contact Tips

| Condition | Bore Diameter | Arc Behavior | Weld Quality |

|---|---|---|---|

| New | Matches wire +0.1–0.3 mm | Stable, centered | Smooth, even bead |

| Worn | Enlarged >0.5 mm | Wandering, flickering | Spatter, porosity |

Maintenance Best Practices

- Store spare tips in a dry, organized kit near your welder.

- Clean tips weekly with a brass wire brush—avoid steel brushes that contaminate copper.

- For heavy spatter jobs, use anti-spatter compound on the tip exterior (not inside the bore).

- Track usage: Log tip changes to predict wear patterns and optimize inventory.

Conclusion: Don’t Let Wear Derail Your Arc

A worn contact tip starts as a minor annoyance but quickly snowballs into rejected welds and frustrated shifts. Make replacement a non-negotiable habit—check after every session, measure the bore, and swap it out. Your arc will stay pinpoint accurate, and your productivity will soar.

Dealt with a stubborn arc from a sneaky worn tip? Share how you caught it below.