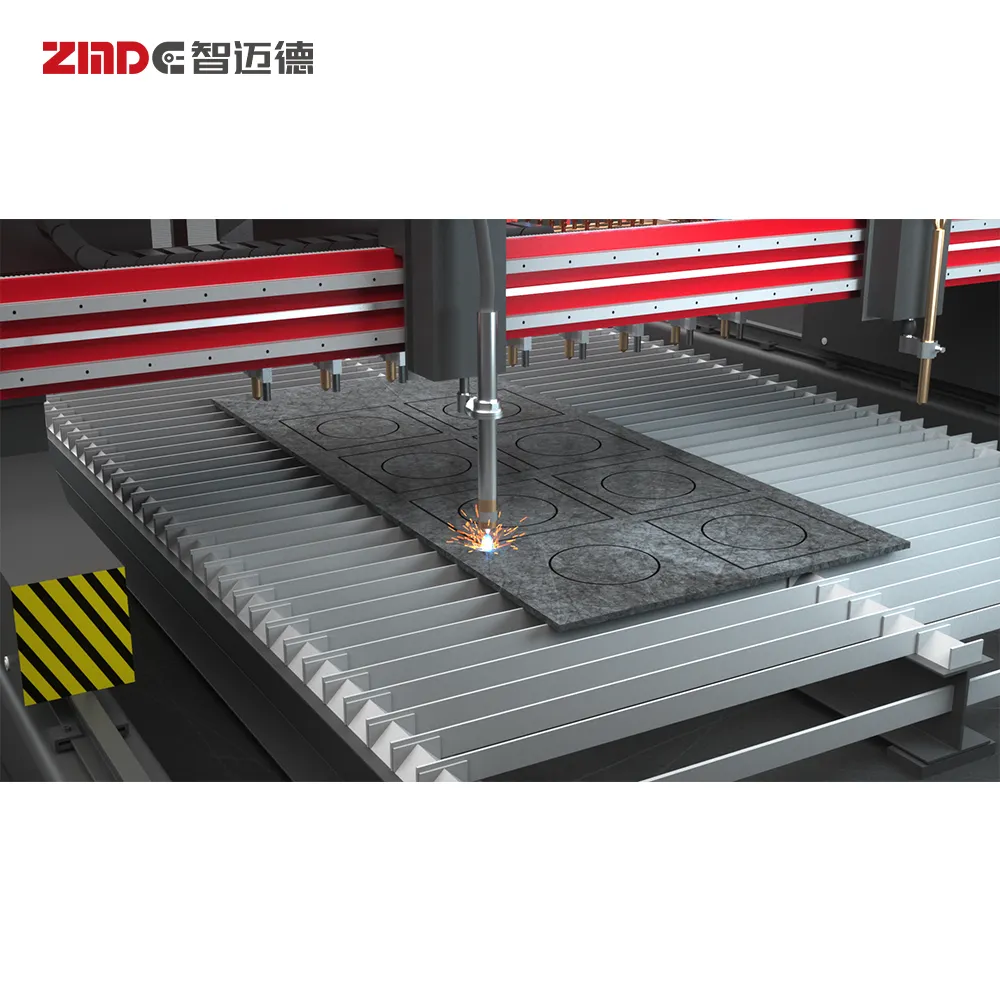

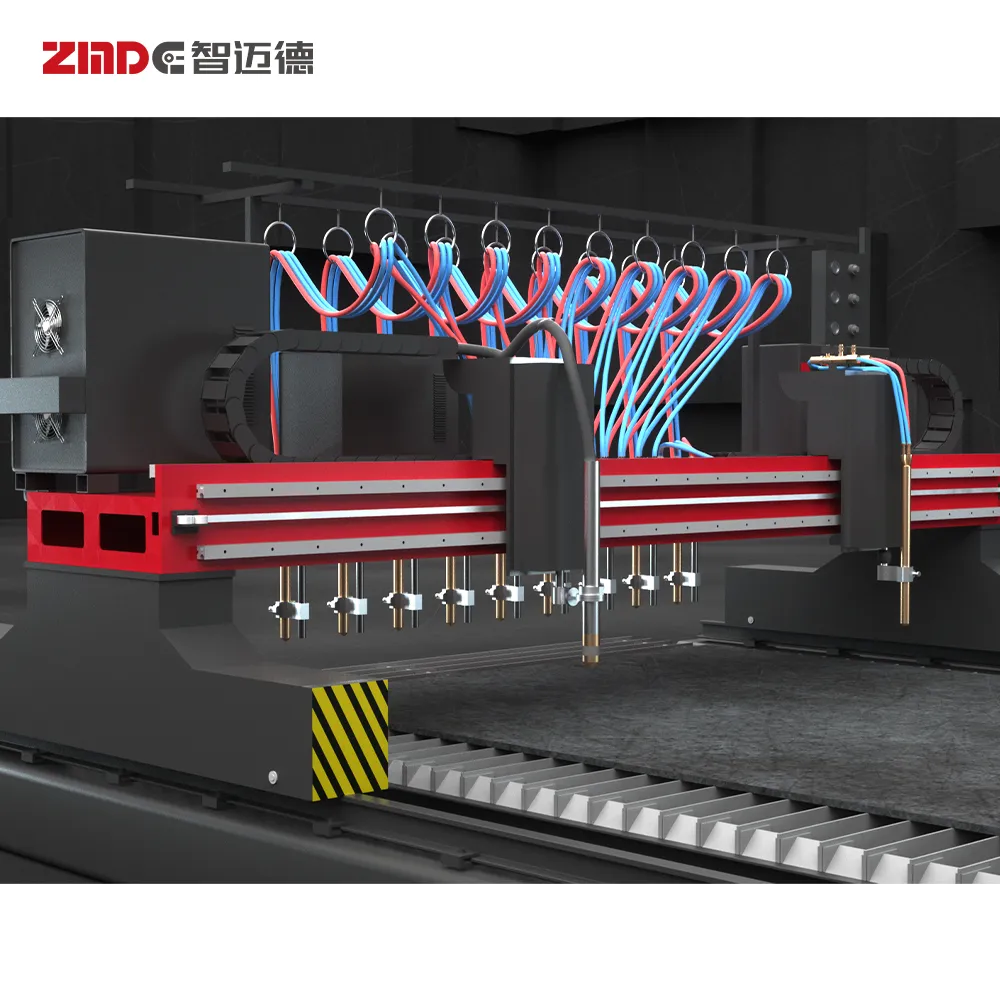

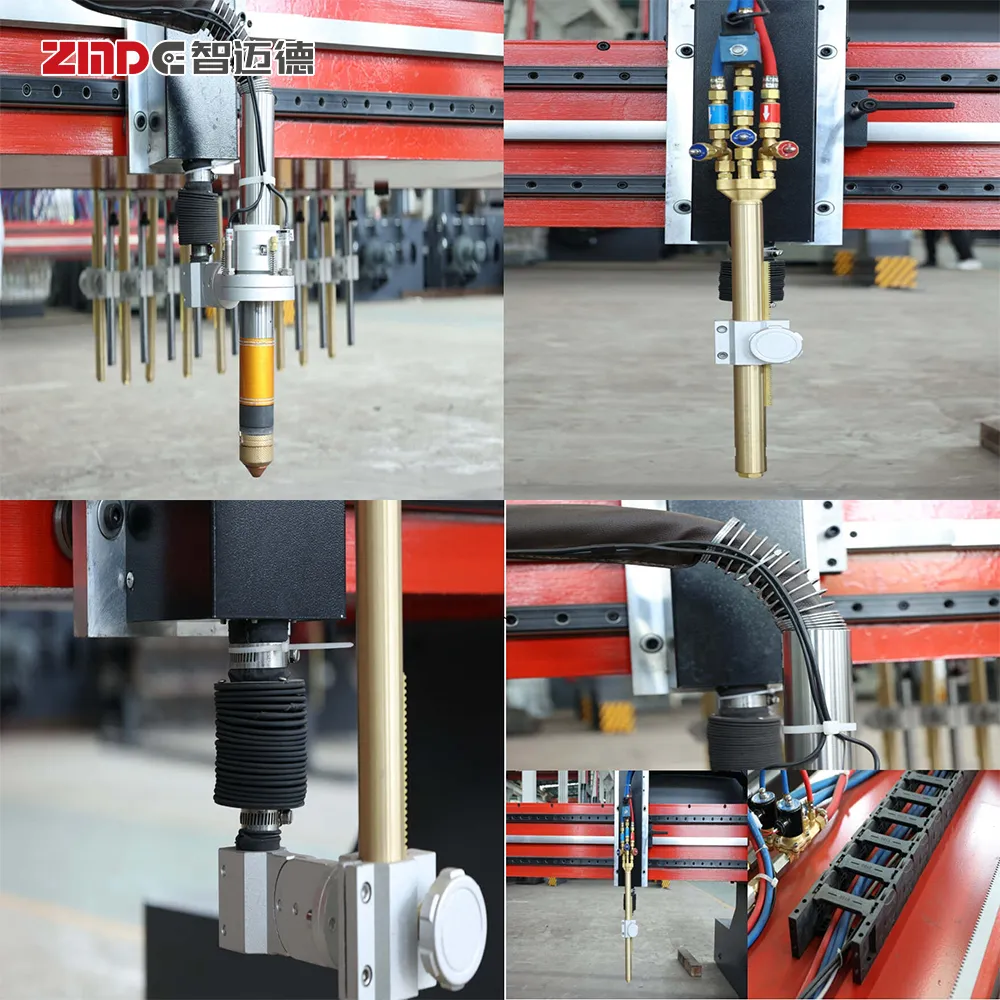

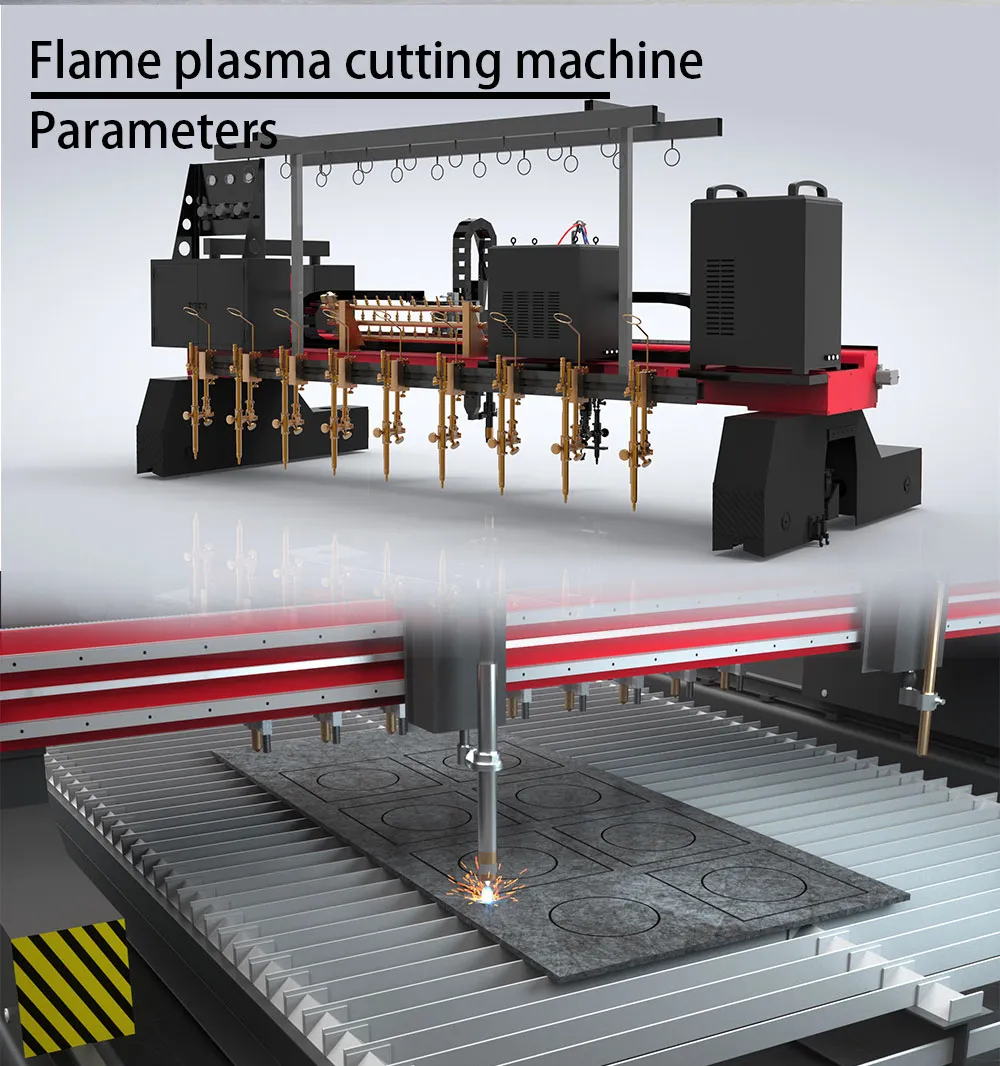

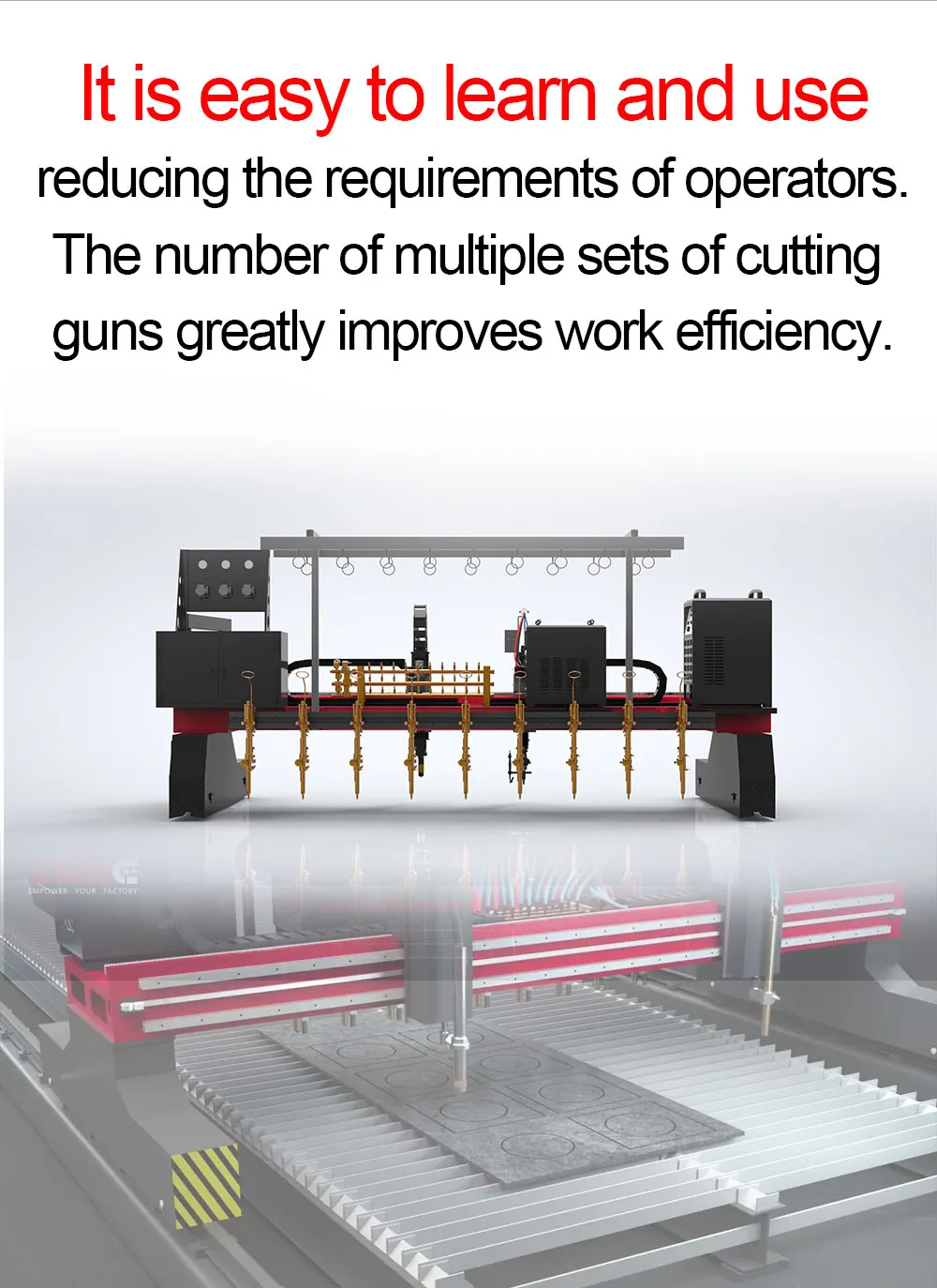

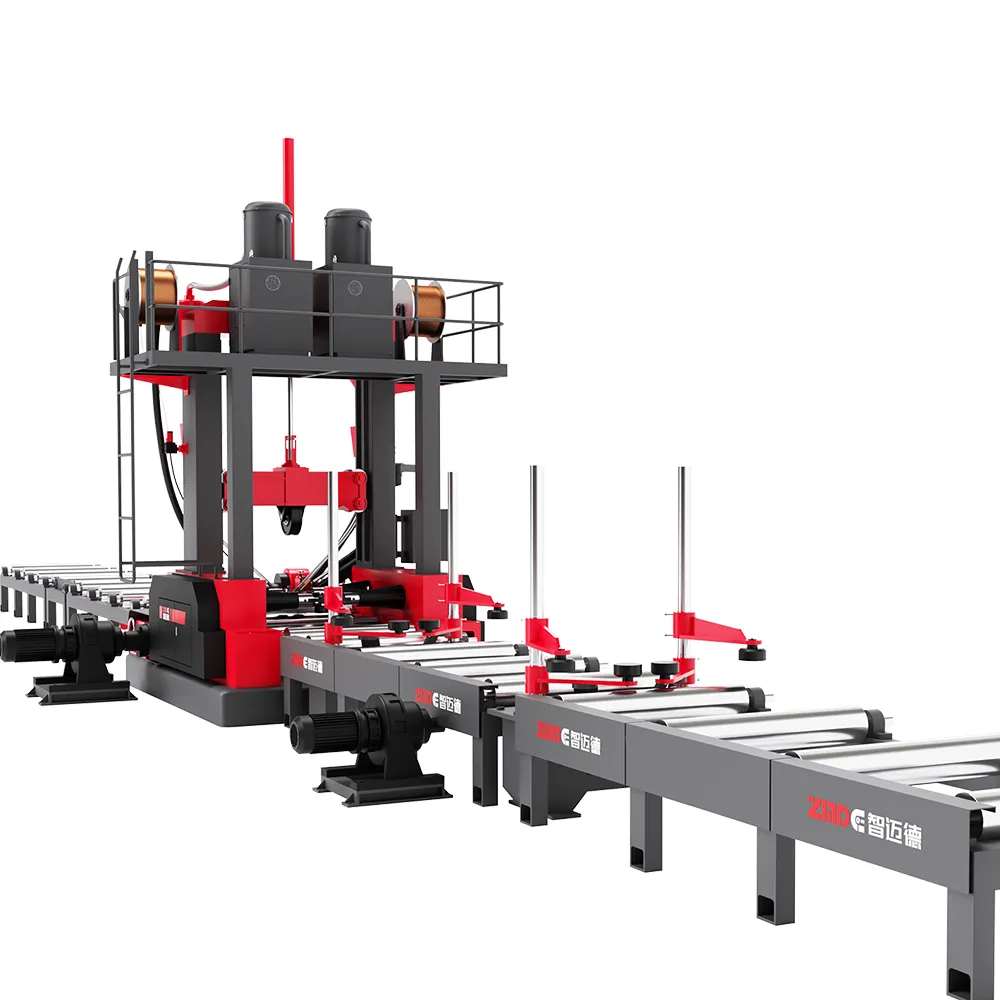

ZMDE Steel Plate CNC Flame/Plasma Cutting Machine FPCM-4000

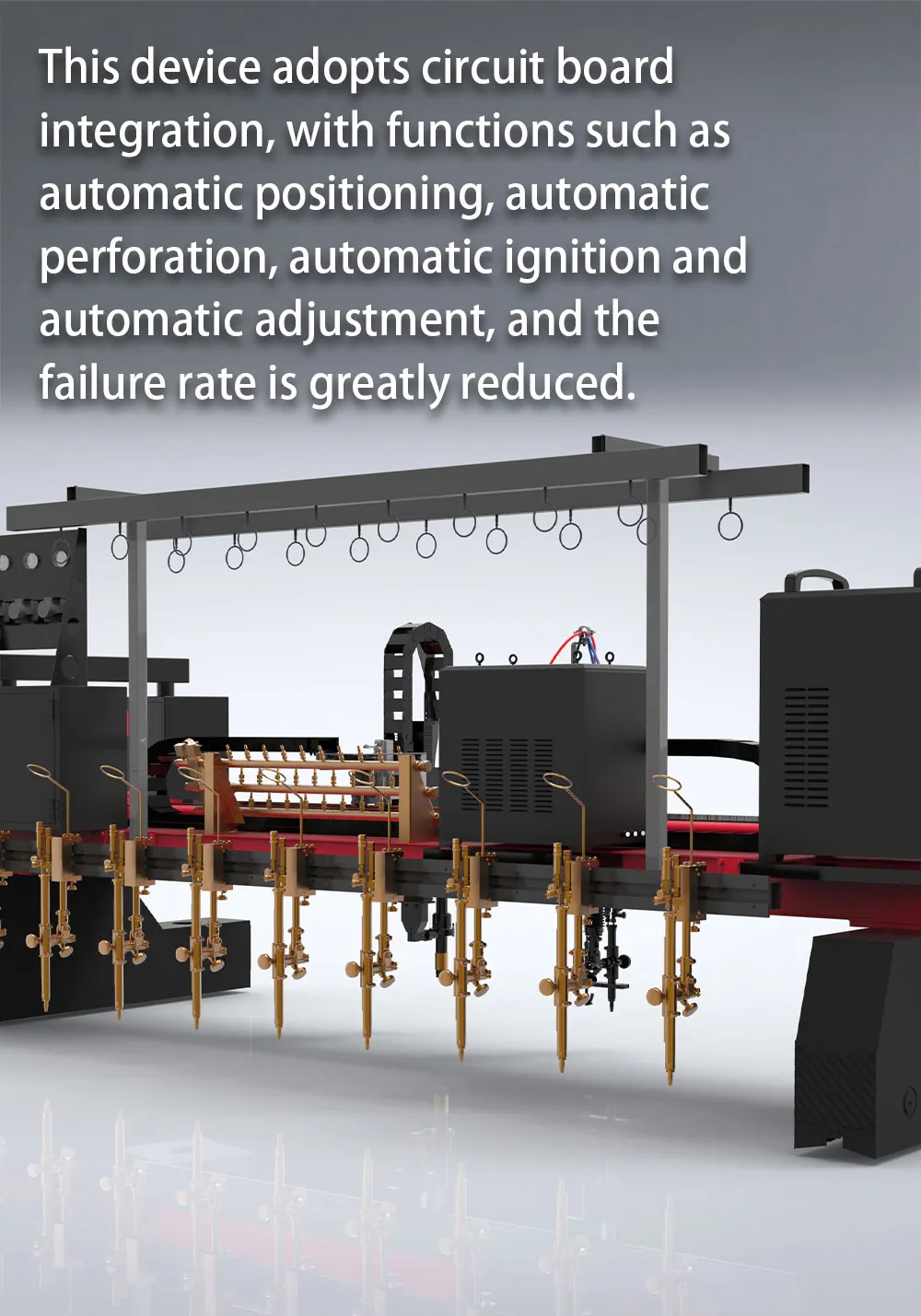

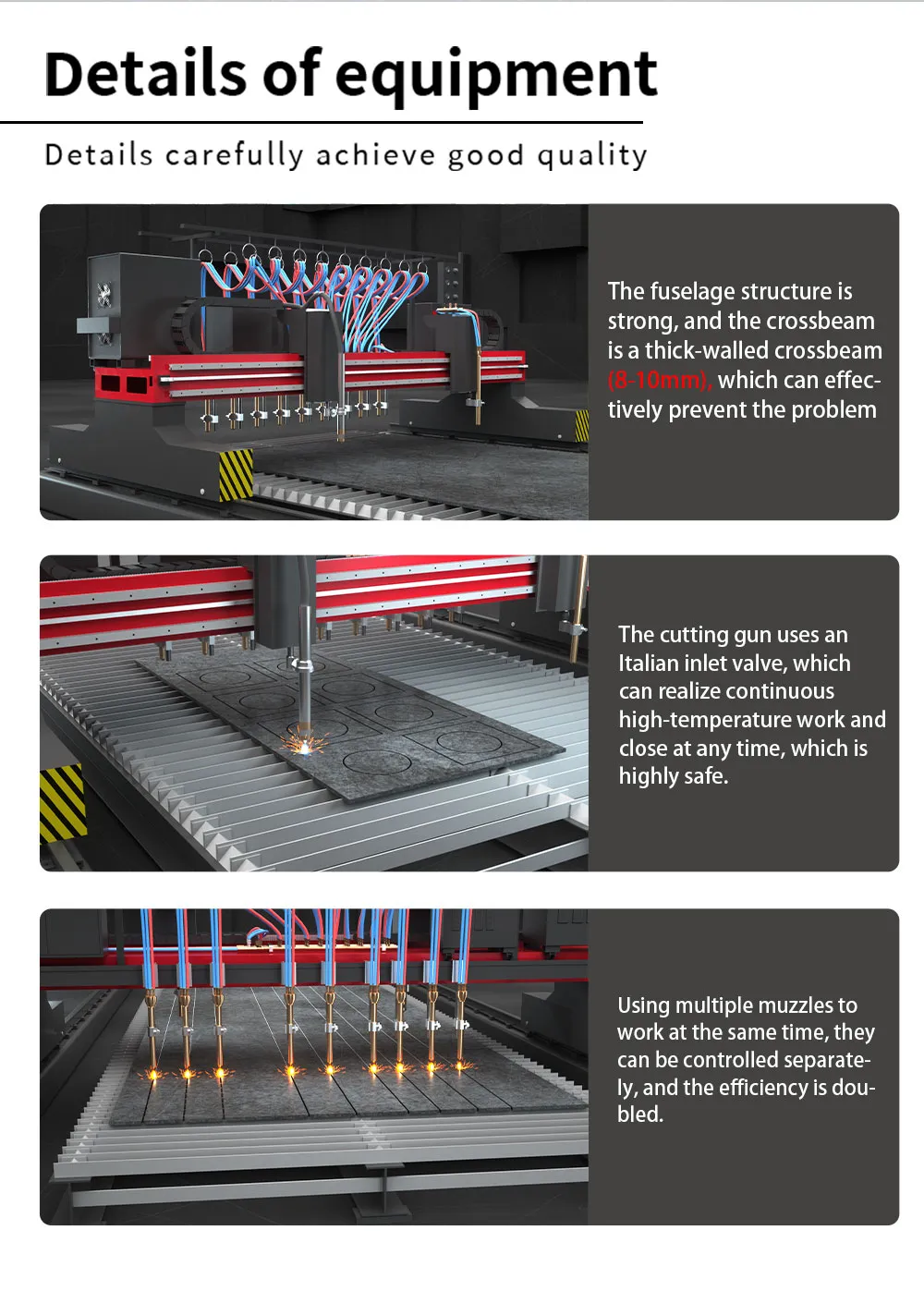

ZMDE Flame/Plasma Cutting machine for cutting steel plate into steel beam in steel fabrication factories.

SKU

ZMDE-FPCM-4000

Category Cutting Machine

Tags CNC, Cutting Machine, Flame Cutting, PEB, Plasma Cutting, Pre Engineered Building, steel fabrication, Steel Plate, ZMDE

Brand: ZMDE

Description

Additional information

| Track Gauge | 4 m |

|---|---|

| Track Length | 14 m |

| Torches Amount | 9 pcs |

| Power Supply | AC 380V, 50Hz, 3-phase |