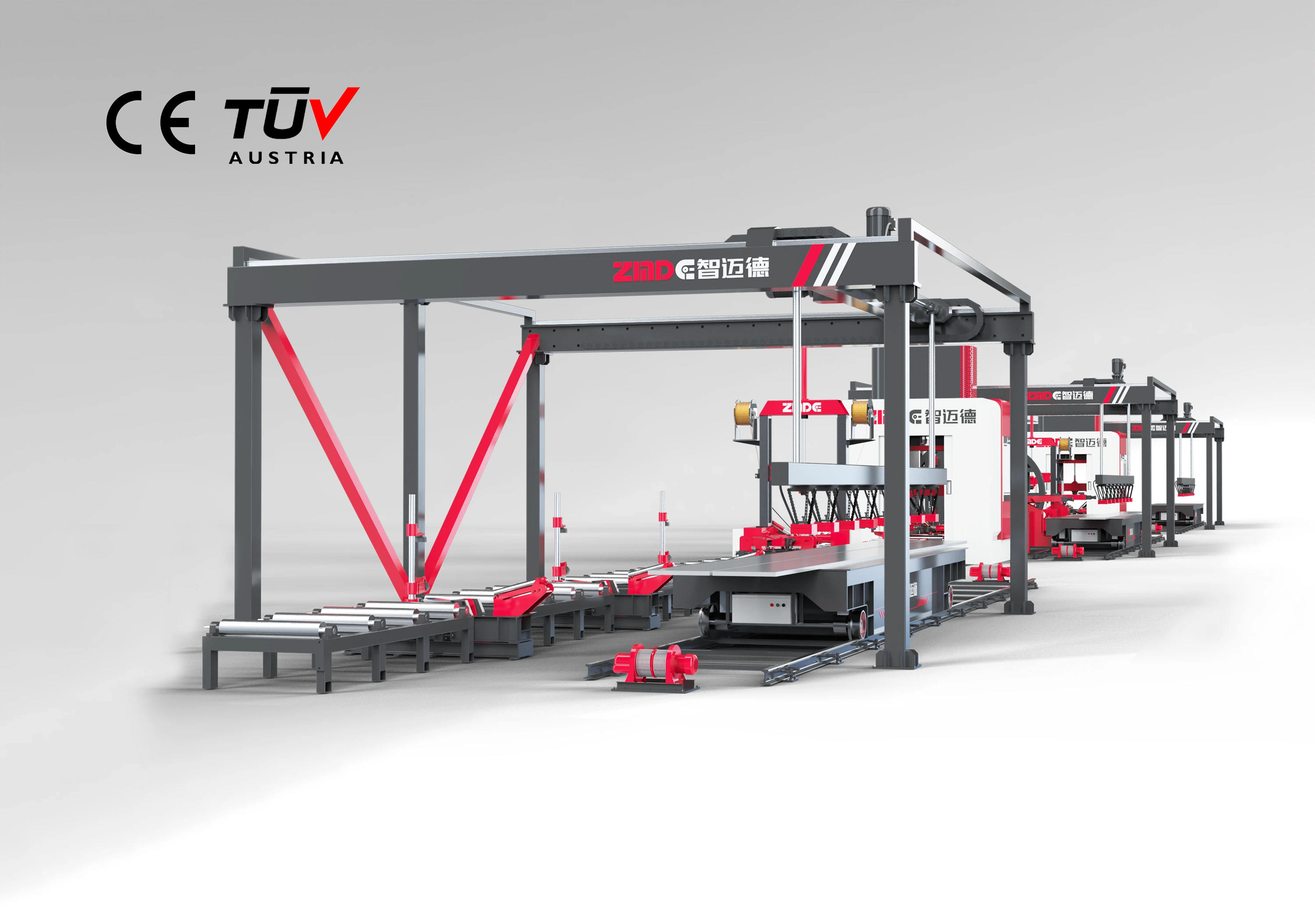

Machine Overview

The ZMDE beam welding machine for H beam automatic production is a game changer in the steel fabrication industry. This innovative system combines assembly, welding, and straightening functions into one efficient platform, specifically designed to enhance the production of H beams.

With its compact footprint, akin to that of a single machine, it is equipped with a digital mobile remote control and an intelligent operating platform, allowing operation by just one person. This feature significantly increases production efficiency and improves the qualification rate of H beam products while also reducing overall production costs.

Utilizing advanced hot welding and straightening technology, the ZMDE beam welding machine enables groove-free welding up to 18mm without striking arc devices. It serves a variety of sectors, including steel structure production, light steel villas, bridges, shipbuilding, high-speed railways, and other industries such as drilling platforms and gas furnaces.

Basic Information

Whole Machine Installation Parameters

Width: 5700 mm

Length: 26000 mm

Height: 4700 mm

Gross Weight: 12.5 tons

(Note: The width includes equipment on both sides and is adjustable between 5500 mm and 6500 mm.)

All-in-One Machine 8 Systems

Machine Configuration

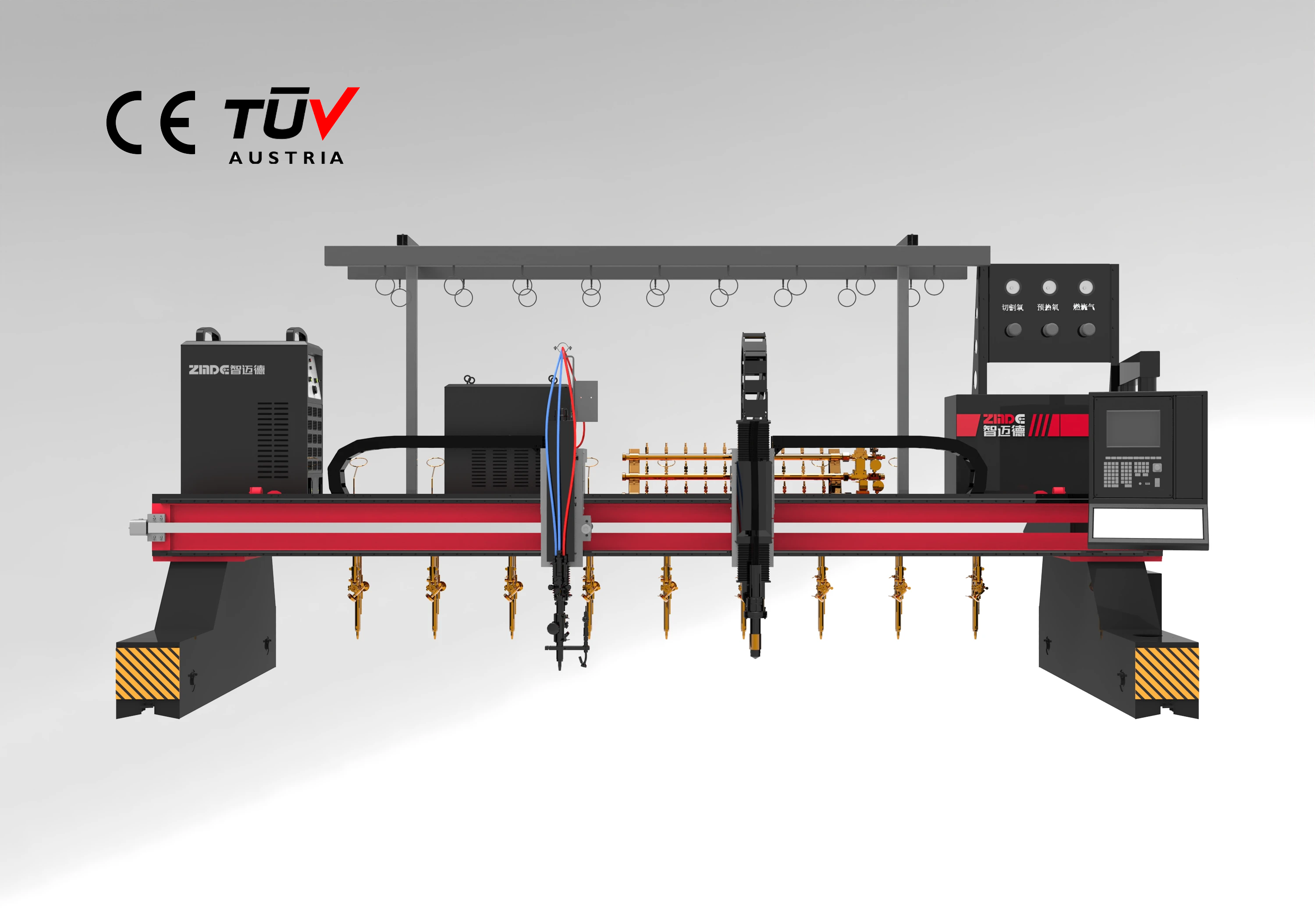

1. Transmisson System

Input Roller Conveyor Section

Roller Conveyor: It consists of three sets of feeding racks (two sets of feeding racks with support racks) + one set of alignment racks, containing 13 rollers with a roller spacing of about 900 mm.

Output Roller Conveyor Section

Output Roller Conveyor: consists of three sets of outfeed racks (two sets with lifting racks) containing 11 rollers.

2. Assembly System

Assembly Machine Part

Roller Conveyor: It consists of three groups of feeding racks (two groups with righting racks) + one group of aligning racks partly, including 13 rollers, with a roller spacing of about 900 mm.

3. Welding System

4. Recycle System

5. Straitening System

6. Hydraulic System

Hydraulic Station: Nine-way solenoid valve, Radiator (the upper box)

From left to right: Feeding for flange panel; Feeding for web plate; Flange plate of main machine; Web plate of main machine; Downward pressure cylinder; Alignment cylinder; Torch rack; Bracket 1; Bracket 2.

7. Electrical System

Control Cabinet: ZMDE patented technology, with controller module controlling the whole motor system.

8. Intelligent Control System

ZMDE independent research and development, perfect match with electrical system and hydraulic system, convenient for human-machine interaction.

Machine Advantages

Cost Recovery Within 100 Days

Comprehensive accounting: 1600 tons of recovered costs. Calculated at 10000 tons per year, profit increases by about 20%

Comparison of Equipment Advantages

Cores Features