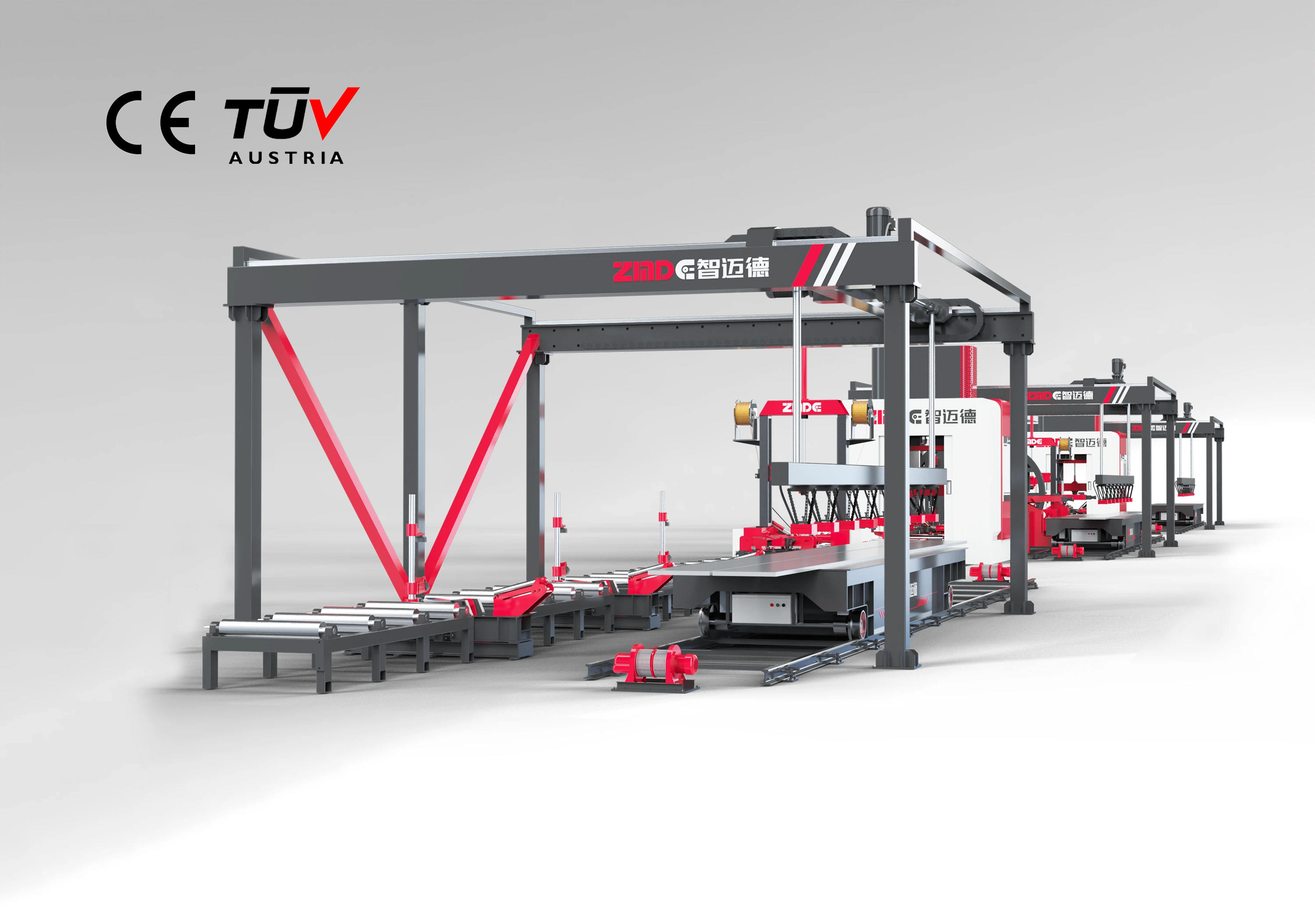

Machine Overview

A CNC welding robot is a versatile automation device used for welding various metal components such as H beams, steel frameworks, and custom structures. It ensures consistent welding quality while improving efficiency and reducing labor intensity. The robot operates with a programmable arm capable of precise rotational and linear movements, making it ideal for both mass production and small-batch manufacturing.

The key components of a CNC welding robot include:

· Robotic Arm: Executes rotational and reciprocal movements for precise welding operations.

· Control System: Manages and programs the robot's movements with high accuracy.

· Welding Head: Delivers consistent welds across various techniques like MIG or TIG.

· Power Supply: Provides stable energy for efficient welding processes.

· Material Handling System: Ensures smooth positioning and movement of workpieces.

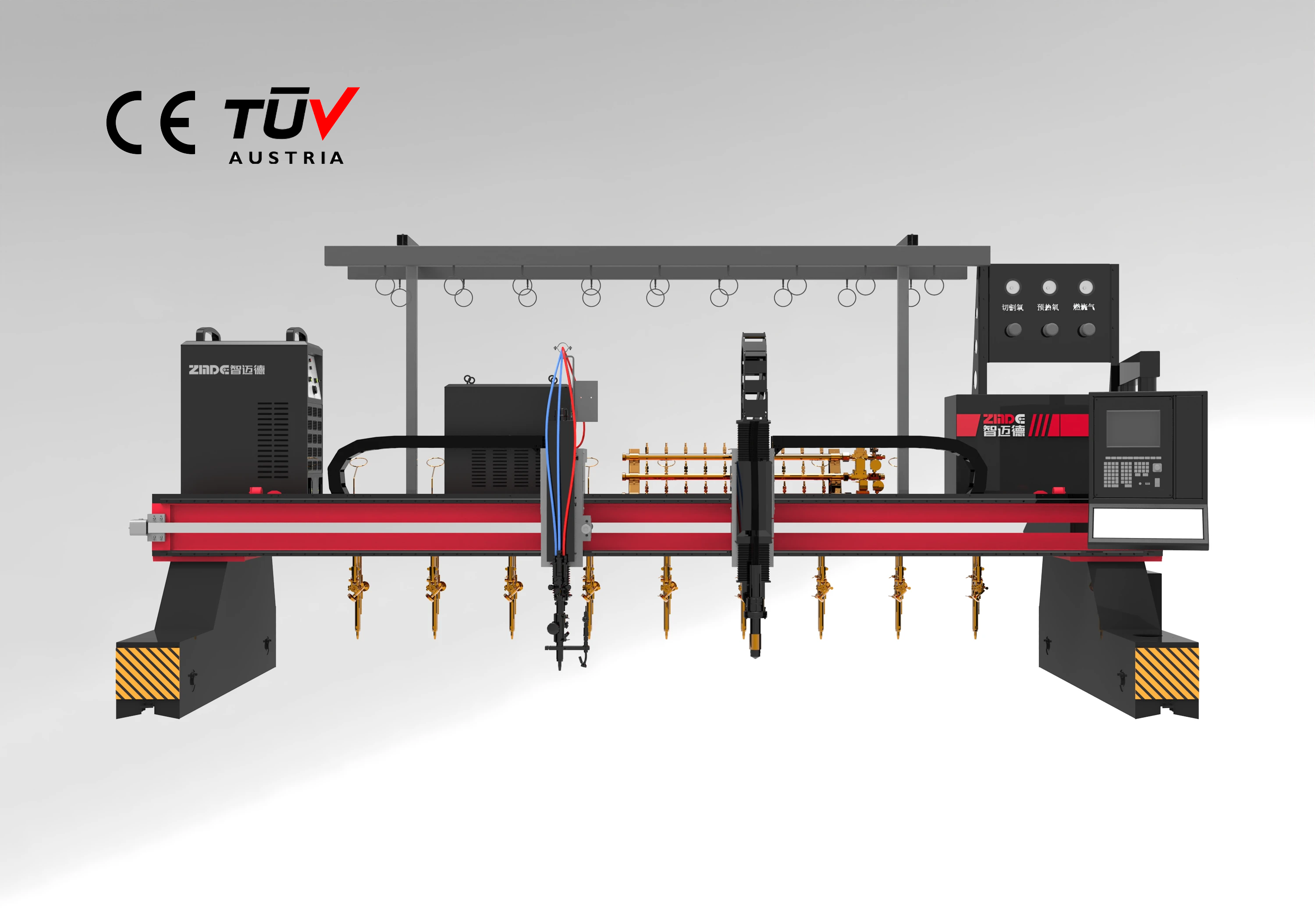

Machine Configuration

Tailor-made Control Systems for Welding

Advantages

01 Multi-external Axes Linkage System

It can support various external axis modes such as linear gantry, ground rail, positioner, etc., and can support up to 14 axis of linkage at the same time.

02 The Richest Welding Process Package in the Industry

Flexible welding machine selection and configuration;

Flight arcing to improve welding efficiency;

After welding, the welding wire is pulled back to improve the success rate of arc striking;

Arc tracking to prevent workpiece deformation during welding;

Laser tracking, laser scanning, laser positioning;

Swing welding, support multiple swing modes, support posture swing, dwell time setting;

Professional welding torch TCP calibration tool;

Intermittent welding to improve programming efficiency;

Dynamically modify welding parameters;

Point laser positioning, welding wire positioning;

Integrated 3D visual weld recognition.

03 Seamlessly Connected Host Computer Offline Programming System

It can support importing the 3D model of the workpiece and automatically generate the welding teaching program.

04 Friendly Interactive Interface

Presentation based on pictures.

05 Excellent Sports Performance

Various transition planning methods: speed planning, path planning, sample planning, smooth and efficient transition;

Support multiple speed planning modes, with high operation efficiency.

06 Multi-sensor Fusion

Support point laser

Support line laser

Support 3D vision