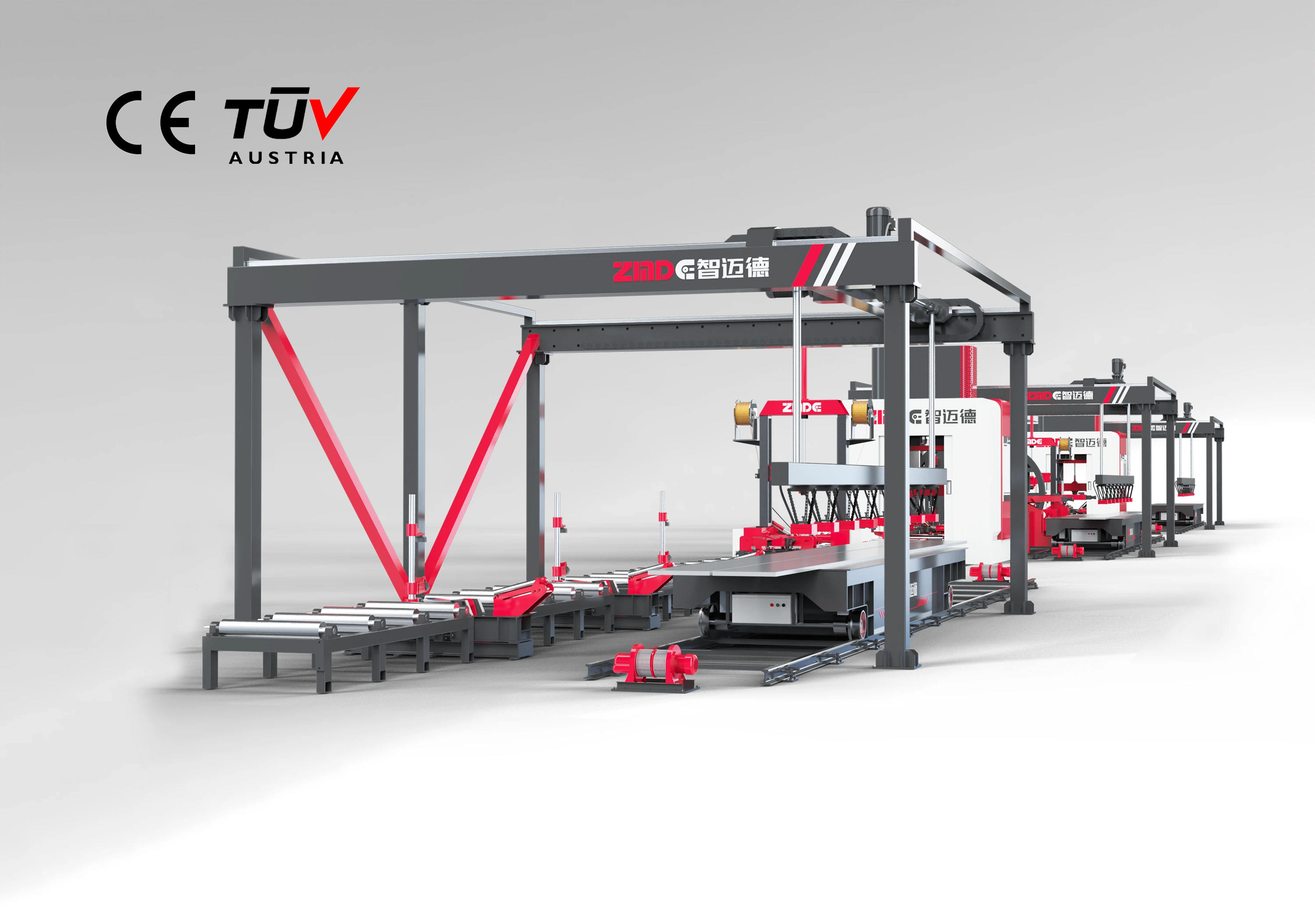

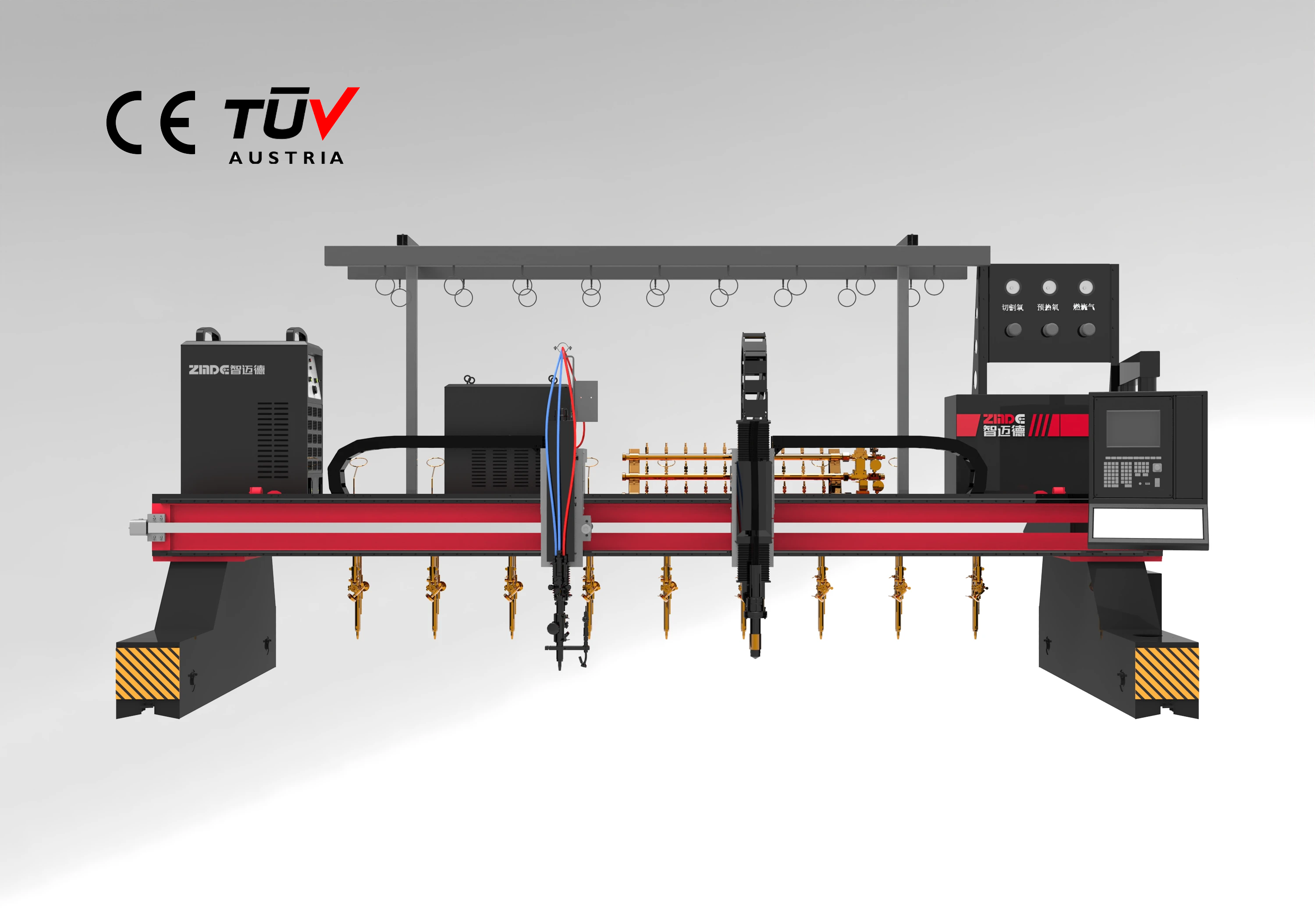

Machine Overview

Explore the forefront of precision engineering with ZMDE's Advanced Laser Cutting Machine, meticulously crafted for the intricate demands of H-beam steel processing. This cutting-edge equipment seamlessly blends robust design with cutting-edge technology, ensuring unparalleled efficiency and pinpoint accuracy in every cut.

At the heart of this machine lies its precision cutting capabilities, engineered to minimize material waste while achieving flawless cutting accuracy. Whether shaping structural components for skyscrapers or intricate designs for specialized machinery, our Laser Cutting Machine delivers consistent, high-quality results.

Effortlessly control and monitor operations in real-time with the machine's intuitive interface, allowing operators to fine-tune cutting parameters with precision. Designed for seamless integration into existing production lines, it optimizes workflow efficiency and reduces downtime, setting a new benchmark in reliability and performance.

Perfectly suited for industries where precision and productivity are paramount, including construction, infrastructure development, and shipbuilding, our Laser Cutting Machine ensures unmatched operational reliability and superior quality. Elevate your manufacturing capabilities with ZMDE's commitment to innovation and precision engineering.

Basic Information

| Model | ZMD-26120L-06 | ZMD-26120L-12 | ZMD-26120L-20 | ZMD-26120L-30 |

| Processing size (length x width) | 12000mm×2600mm(Customizable)

|

| X/Y axis movable range | 12300mm/2650mm(Customizable) |

| Cutting thickness | 0.2-25mm(Depends on material) | 0.2-35mm(Depends on material) | 0.2-40mm(Depends on material) | 0.2-50mm(Depends on material) |

| Minimum line width | <0.1mm |

| Positioning accuracy | +0.2mm

| +0.05mm | +0.2mm | +0.2mm |

| Repeatability | +0.2mm/1000mm | +0.05mm/1000mm | +0.2mm/1000mm | +0.2mm/1000mm |

Maximum empty line speed

| 50m/min |

| Maximum acceleration | 1G

|

| Machine tool dimensions | 14000×4000×1800mm(Customizable) |

| Maximum laser power | 6000W | 12000W | 20000W | 30000W |

| Power supply | AC 380V 50HZ 3Phase |

Cost Analysis

| Laser Power | Assisted gasConsumption | Using air compress or cutting stainless steel

| Using oxygen, cutting stainless steel | Using nitrogen, cutting stainless steel |

6000W

| Power consumption | Laser | 18KW | 18KW | 18KW |

| Water chiller group | 8KW | 8KW | 8KW |

| Host machine | 8KW | 8KW | 8KW |

| Dust exhausting equipment | 3KW | 3KW | 3KW |

| Consumable part | $0.6/h | $0.6/h | $0.6/h |

| Gas consumption | 17KW | $1.4 | $34.8 |

| Total power (Take 80% cutting power) | 37KW | 37KW | 37KW |

| Average power | 29.6KW | 29.6KW | 29.6KW |

| Total operating cost | $7/h | $6/h | $40/h |

| Laser Power | Assisted gasConsumption | Using air compress or cutting stainless steel

| Using oxygen, cutting stainless steel | Using nitrogen, cutting stainless steel |

12000W

| Power consumption | Laser | 36KW | 36KW | 36KW |

| Water chiller group | 12KW | 12KW | 12KW |

| Host machine | 10KW | 10KW | 10KW |

| Dust exhausting equipment | 3KW | 3KW | 3KW |

| Consumable part | $0.8/h | $0.7/h | $0.7/h |

| Gas consumption | 17KW | $1.4 | $41.2 |

| Total power (Take 80% cutting power) | 61KW | 61KW | 61KW |

| Average power | 48.8KW | 48.8KW | 48.8KW |

| Total operating cost | $10.2/h | $8.9/h | $49.2/h |

| Laser Power | Assisted gas consumption | Using air compress or cutting stainless steel

| Using oxygen, cutting stainless steel | Using nitrogen, cutting stainless steel |

20000W

| Power consumption | Laser | 60KW | 60KW | 60KW |

| Water chiller group | 20KW | 20KW | 20KW |

| Host machine | 15KW | 15KW | 15KW |

| Dust exhausting equipment | 3KW | 3KW | 3KW |

| Consumable part | $0.9/h | $0.9/h | $0.9/h |

| Gas consumption | 17KW | $1.4 | $41.6 |

| Total power (Take 80% cutting power) | 37KW | 37KW | 37KW |

| Average power | 78.4KW | 78.4KW | 78.4KW |

| Total operating cost | $14.1/h | $13.1/h | $53.5/h |

| Laser Power | Assisted gas Consumption | Using air compress or cutting stainless steel

| Using oxygen, cutting stainless steel | Using nitrogen, cutting stainless steel |

30000W

| Power consumption | Laser | 70KW | 70KW | 70KW |

| Water chiller group | 30KW | 30KW | 30KW |

| Host machine | 20KW | 20KW | 20KW |

| Dust exhausting equipment | 3KW | 3KW | 3KW |

| Consumable part | $1.1/h | $1.1/h | $1.1/h |

| Gas consumption | 17KW | $1.7 | $48.7 |

| Total power (Take 80% cutting power) | 37KW | 37KW | 37KW |

| Average power | 123KW | 123KW | 123KW |

| Total operating cost | $17.1/h | $19.4/h | $63.4/h |

Cutting Thickness

Cutting Sample Display